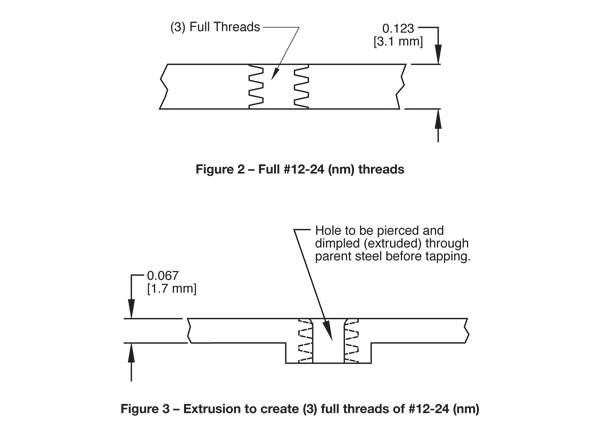

It will need to be punch and dimpled.

Drilled and dimpled door frame.

It may be centered or offset to one side of the opening.

This is a standard option offered by most steel frame distributors and may also be referred to as punch and dimple preps.

A m specialty doors brings its 45 years of combined experience in the manufacturing and installation of commercial entry doors direct to your tool box.

There is either 3 or 4 holes per jamb 3 8 diameter punched and countersunk in the jambs and either 4 or 5 5 is the standard redhead sleeve anchors supplied.

Must grease with lithium grease every 3 4 uses for optimum performance.

Request that the frame manufacturer include existing wall anchors ewa with the frame.

If installing a knock down frame assemble the frame per the manufacturer s instructions.

If you are installing a welded frame remove the shipping spreader bar.

In this video we will demonstrate how to install punch and dimple frames in masonry openings.

The handheld frame dimpler can be utilized in the field or on the assembly line in mass.

You just drill your hole screw the two parts of the dimpler together through the hole and then tighten by hand with two wrenches for a perfect dimple.

Take the nominal door width and add 1.

Locate the correct frame by matching the opening number to the number on the frame.

Quickly dimples common hollow metal door frames.

Determine the placement of the frame within the width of the wall per the job specification.

A standard metal frame has a 2 inch header but many masonry frames have 4 inch headers to allow them to match the masonry coursings.