When the aircraft is on the ground two electric motor pumps emps provide the hydraulic power in each hydraulic system.

Electric motor driven pump aircraft.

Commercial aircraft original equipment manufacturers oems have been building more electric aircraft or mea for over a decade.

These hydraulic pumps are either shaft or electric motor driven and often designed as modules to incorporate numerous functions such as filtration bypass relief pressure and temperature sensing and integral reservoirs.

Wednesday june 12 2019 by aerospace team.

Air cooled electric motorpump mpev3 019 2 1mb eaton s vickers product line ac motorpump model mpev3 019 2 is designed to supply hydraulic power on commerical aircraft.

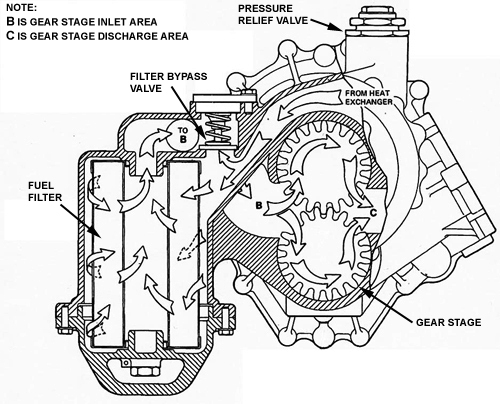

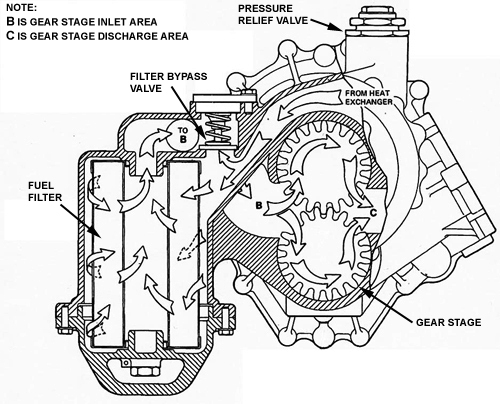

The most common type of auxiliary fuel pump used on aircraft especially large and high performance aircraft is the centrifugal pump.

As a general rule electrical motor pumps are installed for use in emergencies or during ground operations.

Aerocontrolex has extensive experience in the design and manufacturing of aircraft hydraulic pumps for propeller feathering and various aircraft system applications.

To maintain the safety two hydraulic power supply systems operate independently.

Mea are aircraft that rely on electric power to operate non propulsion systems such as those for lubrication flight control fuel thermal management and more.

Power driven pumps are the primary source of energy and may be either engine driven electric motor driven or air driven.

It is electric motor driven and most frequently is submerged in the fuel tank or located just outside of the bottom of the tank with the inlet of the pump extending into the tank.

All aircraft hydraulic systems have one or more power driven pumps and may have a hand pump as an additional unit when the engine driven pump is inoperative.